| The Materials of Book Production | |||

|

|

|

|

| Why Study Early Books? Why should graphic designers study early written manuscripts and books? For a number of reasons: · One can observe the development and logic of page organization into margins, columns, paragraph indents, headers and pagination etc. · It is informative to see various methods of sequencing images and content. · To appreciate the application of text style and typography from a historical perspective. 3 Ways to Evaluate a Books What factors determines the rarity of a book? Age, Scarcity, Condition, First Editions, Fine Bindings and quality of the Illustrations. |

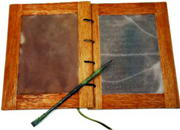

Wax Tablets One of the earliest book forms used wax as a writing surface. A wooden frame was constructed with a thick raised border inside which melted wax was poured to create a wax tablet. When the wax hardened it was scratched with a sharp stylus and colored pigment rubbed over the surface would fill the lines and make the writing more legible. Two panels could be attached and sealed closed for privacy. The wax tablets could travel, be read and then the surface smoothed for reuse. 1

|

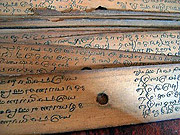

Palm leaves |

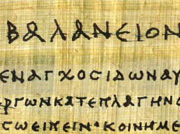

Papyrus A reed plant that grows in water ways contains a stringy cellulose that, when pounded flat, layers into a surface suitable for writing.

|

|

|

|

|

Animal Skins Shortages caused by over harvesting papyrus created a demand for alternative writing surfaces. According to legend, parchment (pergamenum in Latin), was invented by King Eumenes II of Pergamum, deriving its name from the city. Animal skins were a smoother, longer lasting and more flexible surface than those created from plants. Skins from sheep, goats or cows were the most frequently used for manuscripts. (sheep = parchment, calves= vellum). Some believe that the proportions of a book were determined from the sizes made from a folded sheepskin. |

When looking at text pages made of skin it is possible to observe the outer side (hair side) and inner (flesh) side. The hair side has a 'tooth' that holds ink better than the flesh side. Book binders matched the skin to skin (lighter), or hair to hair (darker) sides for uniform page color. Because parchment was so costly it was common to scratch off the surface of a unwanted or obsolete book and rewrite a new text over the old one. The recycled parchments, referred to as palimpsests, still carried evidence of the original text underneath. A famous palimpsest is the Archimedes Palimpsest, a document on which several treatises written by Greek mathematician Archimedes were found on the underlying layer of a Byzantine prayer book.

|

Paper Make from cloth A Chinese official, Cai Lun, is credited with the invention of paper in A.D. 105. His process involved beating mulberry bark, bamboo and fishnets to a pulp and mixing them with enough water to create a loose slurry. (Later the Europeans would use linen or cotton rags for the pulp). A frame with a wire mold was dipped into the mixture and the liquid would run through the screen leaving behind the interlocked fibers. The released paper sheets were pressed flat under pressure to remove the excess water. The paper making process was a closely guarded secret for about 7 centuries until it was extracted from Chinese paper makers held prisoner by the invading Ottoman Turks in 751. Papermaking expertise traveled to Africa by 1150 and spread to Europe through Spain and Italy by the 1200's. In 1283 the first European paper mill was established in Fabriano, Italy. It is still working today, see Fabriano today. 4 |

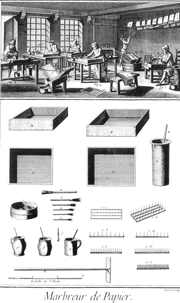

Marbled paper The process of marbling paper originated in China and Persia. The paper is made by dropping blobs of colored paint into a water bath containing carrageen or methyl cellulose (for even distribution of paint). It is sprinkled with a dispersant, such as ox-gall or soap, and swirled with a comb or stick. Marbled paper is mostly used for decorative book covers and end papers. Click on the image below to see the a paper marbling workshop in 18th century France.

To see marbling today watch this Italian marbling workshop video. |

|

This watermark identifies the paper as Fabriano, the first paper mill in Europe. Since the 13th century Fabriano has manufactured hand made paper. |

|

|

Watermarks |

Laid & Wove Papers Laid paper reveals the underlying structure of the screened frame on which is it formed from liquid pulp. In the mid-1700's James Whatman developed a paper in which the fibers did not line up into a discernable pattern — wove. This allowed for a smoother surfaced paper which was suitable for letterforms with delicate line weights. Here is a link to the story of the Whatman paper project. |

Calendared paper

Calendared paper has been run through roller under extreme pressure to create a smooth sheet of paper. For a glossy effect the paper can be coated with a clay surface which creates a shine. Calendaring can also be applied to fabric and polymer sheets. |

|

| Paints, Inks and Pens | |||

|

|

|

|

| Ink Early ink ingredients were made from natural materials such as the secretions of cuttle fish, (sepia) or a mixture of soot and gum, iron gall, lamp black or black walnut. Two medieval recipes : one used carbon ink, made of charcoal or lamp-black mixed with a gum, another used metal-gall ink, usually iron gall, made by mixing a solution of tannic acids with ferrous sulphate (copperas); it too requires added gum, but as a thickener rather than as an adhesive. The blackness is the result of a chemical reaction. "Galls contain large amounts of tannic acid, which was used for making iron gall ink and for dying cloth. According to recent research, traces of iron-gall ink have been found on the Dead Sea scrolls and on the 'lost' Gospel of Judas. Iron-gall ink may have been used for 1,800 years, but it does not withstand the test of time well. Over the course of centuries, the ink fades, and discolors and damages the paper. Other water-proof formulae, better suited for writing on paper, became available in the 20th century. Iron gall ink is manufactured chiefly by artists enthusiastic about reviving old methods or possibly forgers of old documents. A recipe for preparing the ink is as follows: Take one lb. of bruised galls, one gallon of boiling water, 5 1/2 oz of ferrous sulfate in solution, 3 oz of gum arabic previously dissolved, and a few drops of an anti-septic, such as carbolic acid. Macerate the galls for 24 hours, strain the infusion and add the other ingredients." 7 |

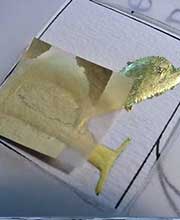

Gold Leaf Silver or gold leaf was used on manuscripts to invoke spirituality. The 'leaves' were made by hammering metal coins into thin sheets that were lighter than air. The areas to be illuminated were first painted with gesso, then sheets of gold leaf were placed over the sticky, wet substance. The gold leaf adhered only to the wet gesso. When the gesso dried, the remaining gold was carefully removed with a soft brush or a feather and burnished.

Metallics were applied and burnished before the colored paints to avoid later rubbing off the color.

|

Illumination Pigments

8 Elaborate manuscripts were often 'illuminated' with multiple colors. Early scribes prepared their own pigments. There is evidence that in the early 13th century some scribes began purchasing ingredients from stationers and some standard colorants began to emerge. Pigments used by the medieval painter were the rich, dark blue of lapis lazuli or azurite, vermilion red, verdigris and malachite green. Powdery pigments were mixed with a binding medium (such as honey to earwax) into a workable medium that could be applied as paint. Common media used as binders were egg-tempera and gum-arabic.

The most expensive color was the blue that came from lapis lazuli, a semi-precious stone imported from Afghanistan (below). The illuminated paintings were known as miniatures not a reference to their size but to the Latin term, minum, which refers to red pigment.

|

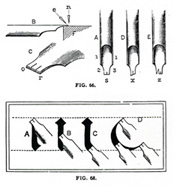

Quills

Writing quills were made from the first five flight feathers from the wing of any bird. Quills from birds as large as geese or swans or as small are sparrows were used depending on the size of the text required. Quills provides a sharp stroke as well as greater flexibility than a steel pen but are labor intensive to make and must be frequently sharpened. The hollow shaft of the feather (the calamus) acts as an ink reservoir and ink flows to the tip by capillary action. Preparing a feather pen is a long process. First the feather plume is removed and then the quill is tempered (seasoned by standing in hot sand) for strength and flexibility. The point of the quill is cut away at an angle. To see a video and description on how to cut go here.

10

|

| Footnotes | |||

1 2 3. 4. |

5 6 8

|

9 10 |

|

| Copyrights | |||

| ©Designhistory.org 2011 | For Permission Info click here | ||